- #Eplan demo how to#

- #Eplan demo pro#

The third section shows how a symbol table is created ( Task 3 - Creating the symbol table).In the second section addresses for the inputs and outputs are assigned ( Task 2 - Allocating addresses for the inputs and outputs).The first section shows how a Step7 program is to be created for the Feeder example machine ( Task 1 - Creating the Step 7 program for Feeder).This discipline is divided into four sections:

#Eplan demo how to#

The PLC discipline is used to show how to create a program for SIMATIC Step 7 based on the mechatronic model. The test at the end of the section on Setting a disabler for digital input cards shows how a cabinet that is adapted to the installed components can be created with the aid of the disabler concept.

#Eplan demo pro#

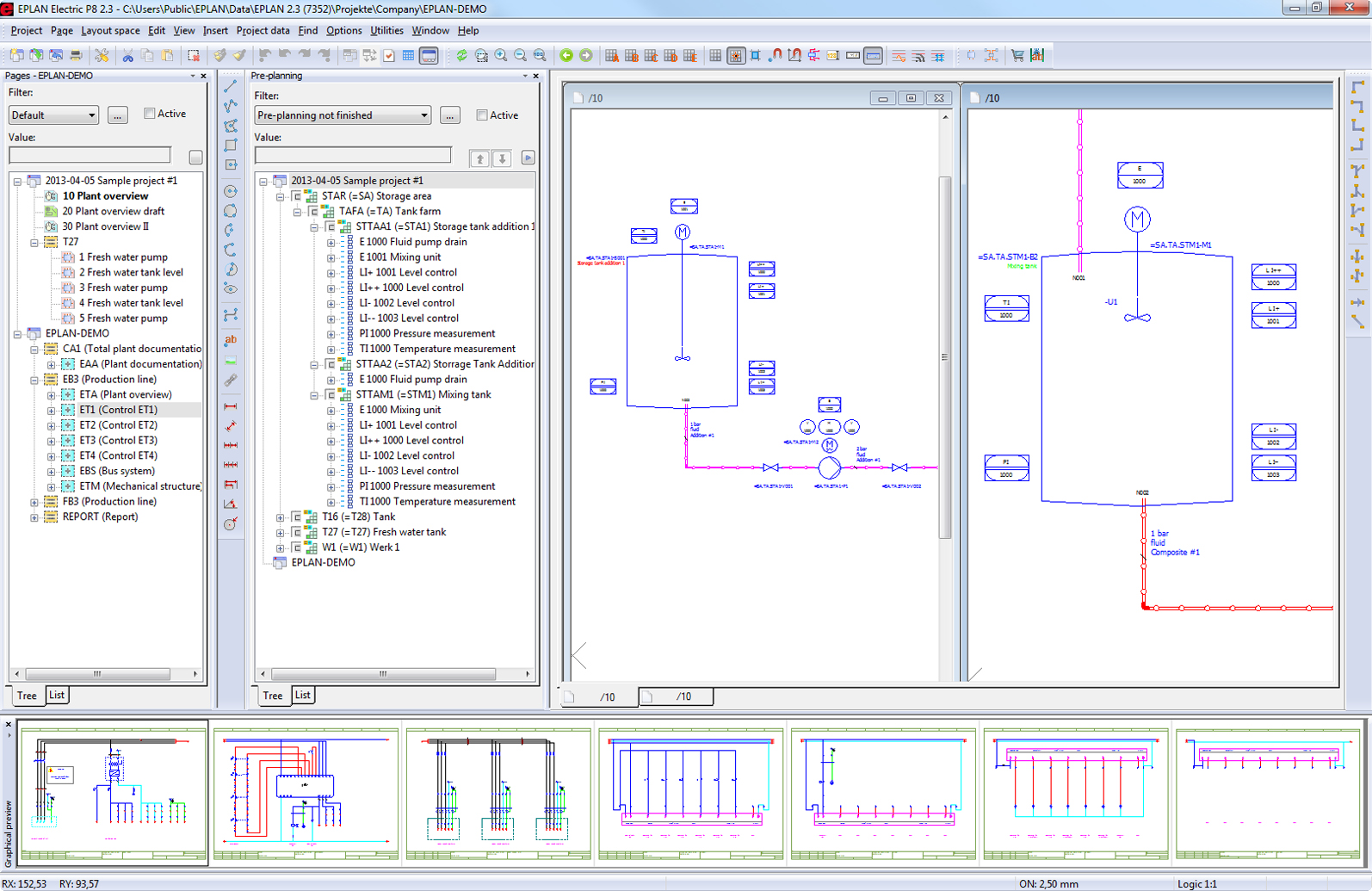

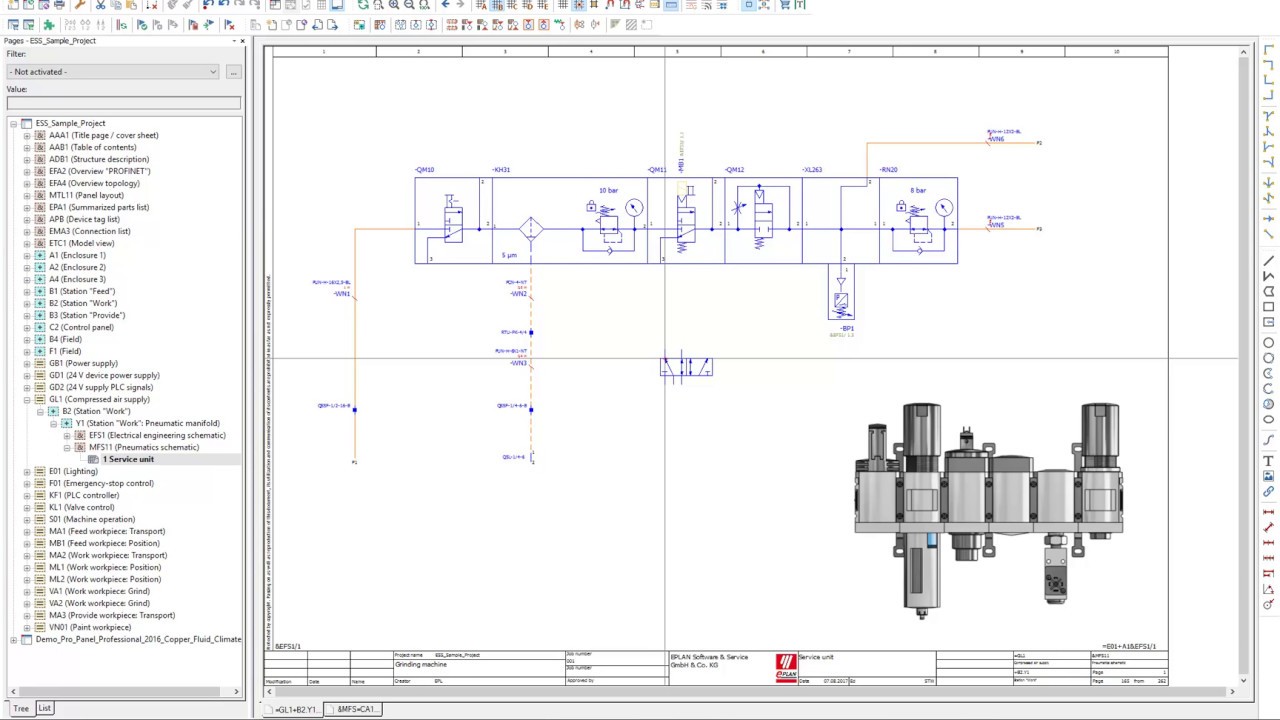

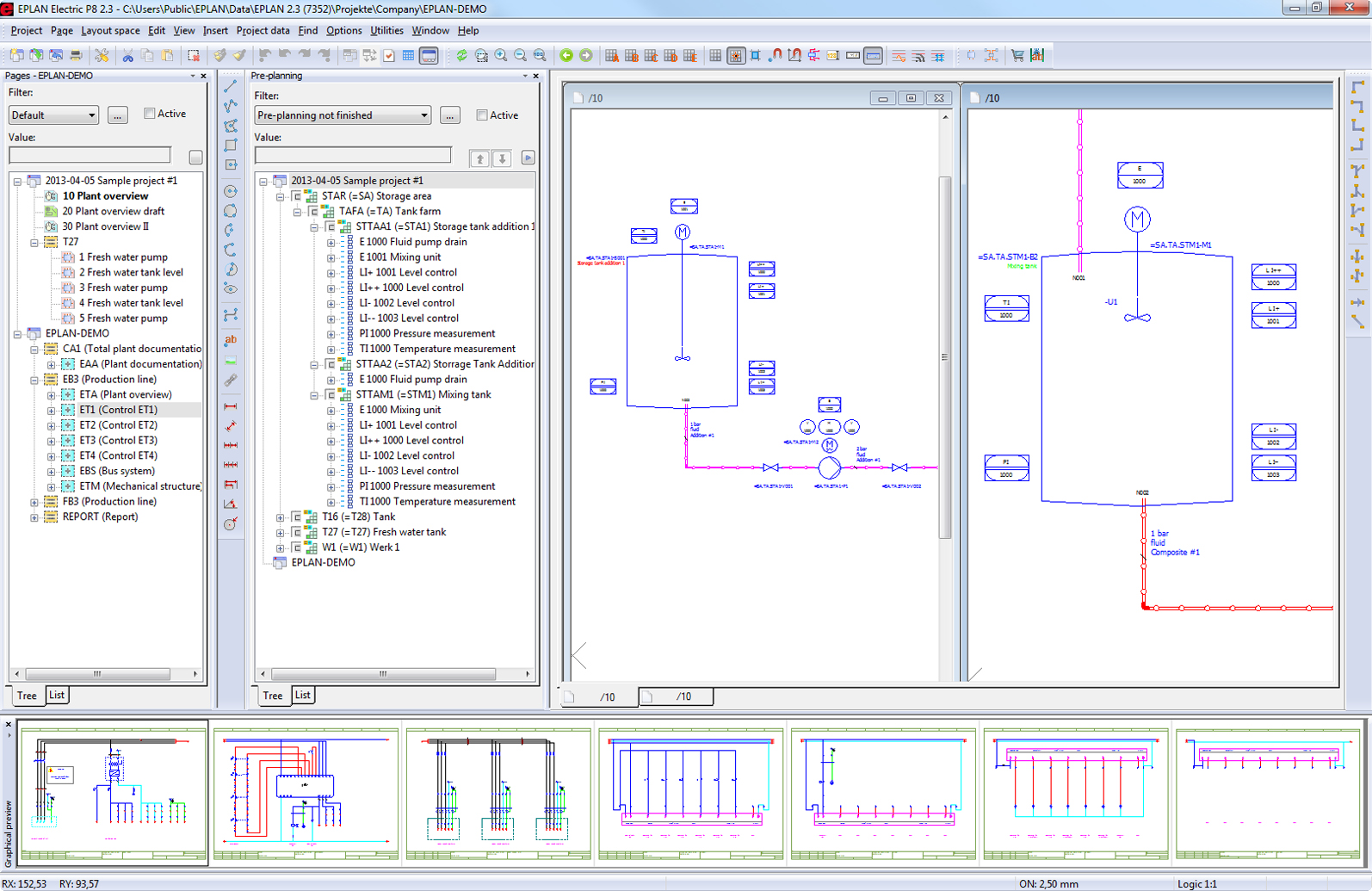

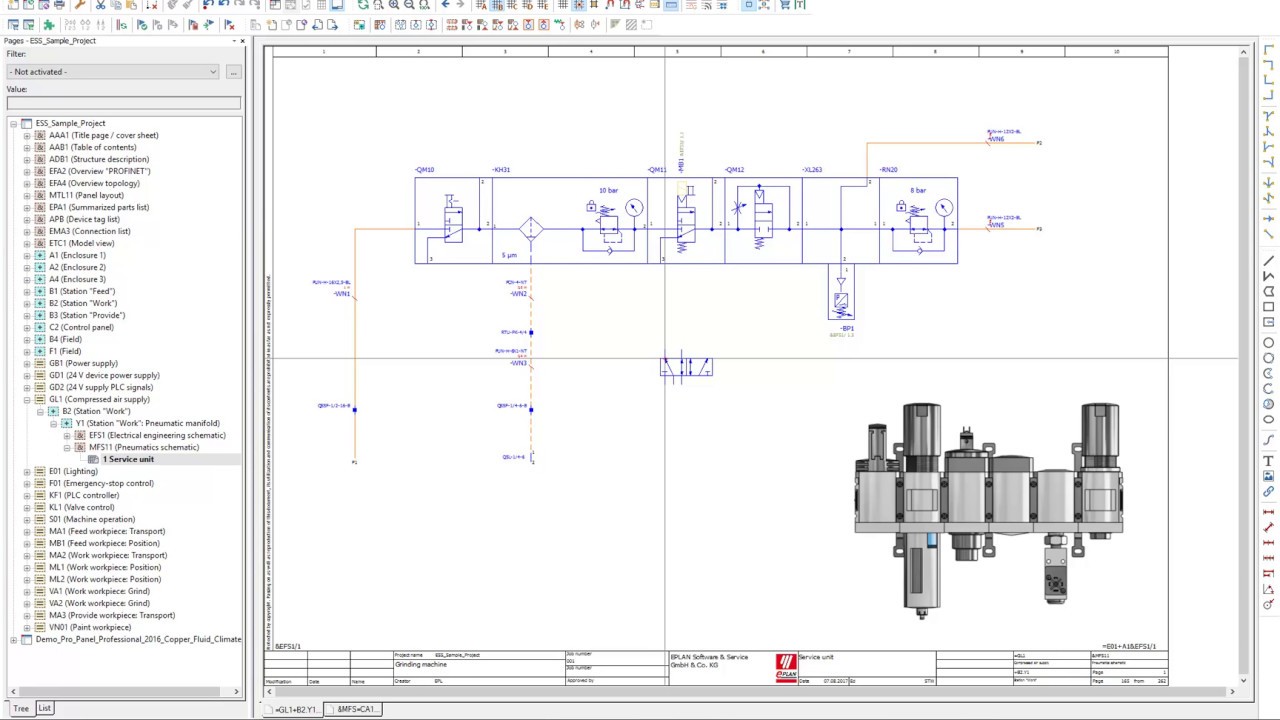

The EPLAN Pro Panel discipline is then added to the existing mechatronic model for the feeder ( Expanding the mechatronic model with EPLAN Pro Panel components).  The first step is to Creating EPLAN Pro Panel discipline components for this discipline. The Pro Panel discipline shows how a schematic for EPLAN Pro Panel can be created on the basis of the mechatronic model. The test at the end of the chapter Use formulas for plugs, sockets, and PLC inputs shows how to create a schematic that is aligned to the installed components on the basis of the plug-socket concept. The EPLAN Electric P8 discipline is then added to the existing mechatronic model for the feeder ( Adding the schematic discipline to the mechatronic model). The first step is to Create EPLAN Electric P8 components for this discipline. The ECAD discipline shows how a schematic for EPLAN Electric P8 can be created on the basis of the mechatronic model. How it possible to use the plug-socket concept to create a list of components that differs in structure from the functional layer is demonstrated in the section Mechatronic model: Generating non-functional structures. The ListOfComponents discipline is then added to the existing mechatronic model for the feeder ( Adding the ListsofComponents discipline to the mechatronic model). The ListOfComponents is to be seen as the created results of a new discipline (see Task: Generate a ListOfComponents). The Generation of variants via disabler and the Generation of variants via parameterization are explained in separate sections.Ī list of actuator and sensor components is used as an example to demonstrate how it is possible to create a text file from the mechatronic model using the Text discipline:. This then serves as the basis for configuring the feeder mechatronically ( Configuration). Building on this, the components required for the feeder are specified ( Develop mechatronic modular system). In the first step, the basic architecture is defined ( Create a mechatronic architecture model). Once the example machine has been visualized, the development of the Mechatronic is described as follows: Next, the resulting architecture model is visualized ( Architecture model). The functional assembly is used to create the abstract Mod. The diagram of the example machine serves as the basis for the Functional assembly. Presentation of the example machine ( Example Feeder): The purpose of every discipline is to create files such as a list of components or a schematic diagram. These can be created separately from each other. The modular system for the feeder can be expanded to include disciplines. Once the example machine has been visualized, the next step is to create a mechatronic modular system (feeder). The tutorial is structured so that each chapter can be completed on its own (see figure below). This film shows a cycle of the demo assembly in operation. The resulting modular system is used to create a Feeder station, a demo assembly developed at the Esslingen University of Applied Sciences: The step-by-step development of a modular system will be used to demonstrate functional configuration.

The first step is to Creating EPLAN Pro Panel discipline components for this discipline. The Pro Panel discipline shows how a schematic for EPLAN Pro Panel can be created on the basis of the mechatronic model. The test at the end of the chapter Use formulas for plugs, sockets, and PLC inputs shows how to create a schematic that is aligned to the installed components on the basis of the plug-socket concept. The EPLAN Electric P8 discipline is then added to the existing mechatronic model for the feeder ( Adding the schematic discipline to the mechatronic model). The first step is to Create EPLAN Electric P8 components for this discipline. The ECAD discipline shows how a schematic for EPLAN Electric P8 can be created on the basis of the mechatronic model. How it possible to use the plug-socket concept to create a list of components that differs in structure from the functional layer is demonstrated in the section Mechatronic model: Generating non-functional structures. The ListOfComponents discipline is then added to the existing mechatronic model for the feeder ( Adding the ListsofComponents discipline to the mechatronic model). The ListOfComponents is to be seen as the created results of a new discipline (see Task: Generate a ListOfComponents). The Generation of variants via disabler and the Generation of variants via parameterization are explained in separate sections.Ī list of actuator and sensor components is used as an example to demonstrate how it is possible to create a text file from the mechatronic model using the Text discipline:. This then serves as the basis for configuring the feeder mechatronically ( Configuration). Building on this, the components required for the feeder are specified ( Develop mechatronic modular system). In the first step, the basic architecture is defined ( Create a mechatronic architecture model). Once the example machine has been visualized, the development of the Mechatronic is described as follows: Next, the resulting architecture model is visualized ( Architecture model). The functional assembly is used to create the abstract Mod. The diagram of the example machine serves as the basis for the Functional assembly. Presentation of the example machine ( Example Feeder): The purpose of every discipline is to create files such as a list of components or a schematic diagram. These can be created separately from each other. The modular system for the feeder can be expanded to include disciplines. Once the example machine has been visualized, the next step is to create a mechatronic modular system (feeder). The tutorial is structured so that each chapter can be completed on its own (see figure below). This film shows a cycle of the demo assembly in operation. The resulting modular system is used to create a Feeder station, a demo assembly developed at the Esslingen University of Applied Sciences: The step-by-step development of a modular system will be used to demonstrate functional configuration.

0 kommentar(er)

0 kommentar(er)